Technical office

Our engineering department consists of highly professional staff and experience has sophisticated 3D modeling software of the latest generation for the creation of custom projects.

From the initial stages of the project we provide the necessary advice for the proper implementation of the mould.

By means of the copying machine through reverse engineering we can import on the pc existing models with the ability to make changes or starting from a draft on paper or by importing the mathematical supplied by the customer.

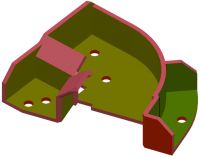

We can faithfully carry out the three-dimensional rendering of detail allowing making any changes prior to the final realization of the mould so as to reduce the time and costs and increase quality.

The software we use are continuously updated allowing to realize thanks to surface and solid modeling whatever technical product functionality and design to meet all customer requirements.

Have workstations equipped with advanced CAM software for the programming of the machine tools with numerical control and generating tool paths for milling.